This article first appeared in IAM Issue 100, published by Law Business Research – IP Division. To view the issue in full, please go to www.IAM-media.com.

Developments in technology promise to usher in a new era of manufacturing, making it a matter of urgency for rights holders to ensure that they have the appropriate level of protection for their intangible assets.

Ever since the concept of 3D printing, also known as additive manufacturing, was proposed in the late 1970s, this technology has rocketed from being niche into an industry that is projected to be worth $6.5 billion by 2024.

While this figure is just a fraction of the value of global manufacturing, the 3D printing industry’s consistent double-digit growth indicates that it will have an increasingly significant role to play in both the production of goods for the mass market as well as for individuals.

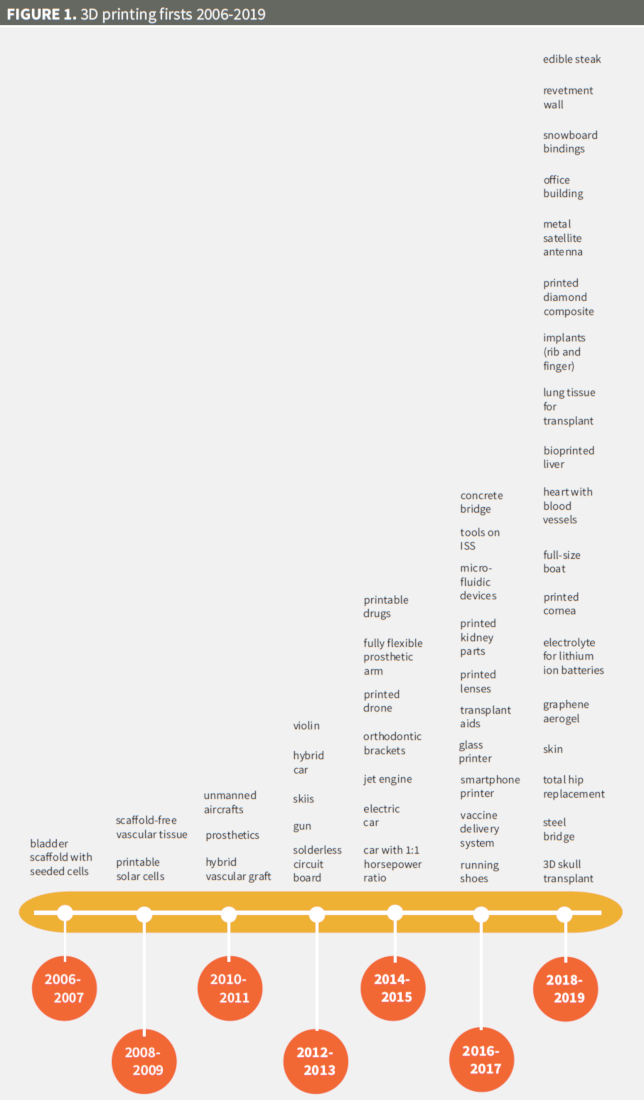

As Figure 1 illustrates, the range of products that can be printed and the variety of materials that can be used is growing steadily. The number of industries standing to benefit from this technology is constantly rising – no longer solely the remit of hobbyists or for rapid prototyping, it is now moving mainstream and provides a very real alternative to traditional manufacturing methods. Although this currently applies to a relatively limited range of products, its scope of use is expected to widen in coming years.

The attraction of 3D printing is clear. Products can be manufactured quickly and on demand and easily customised to the end user. This is particularly valuable for the spare-parts market. Gone are the days where large quantities of parts had to be stocked in various locations and then shipped around the world as requested.

Further, additive manufacturing paves the way for distributed manufacturing as it is a means for making complicated products easily and without a highly skilled workforce. Accordingly, items no longer need to be centrally manufactured *en masse* in low-cost markets and shipped to consumers. Instead, production can be carried out locally, thereby reducing transportation costs and speeding up delivery.

The benefits of this are huge. It not only reduces the amount of capital bound in storage but also allows repairs for products to be supported over a longer lifespan. This will save businesses money and has the potential to fundamentally disrupt existing business models, supply chains and business-to-customer relationships.

These are just some of the advantages offered by additive manufacturing. Moreover, the gains even apply to products that were previously produced using traditional manufacturing methods.

Complexity made simple

Another crucial positive for 3D printing is that it enables products and designs that were not previously possible. This has proven to be a tremendous driver for R&D, resulting in a growing list of additive manufacturing firsts (see Figure 1). With increasing innovation comes enthusiastic adoption, which leads to larger manufacturing volumes. This in turn motivates innovation and competition in raw material supply, thus expanding the range and quality of printable, economically viable products.

Figure 2 illustrates the number of patent applications published in the 3D printing field since 2012 (based on patent publications in International Patent Classification Classes B33Y and B29C64/00). The numbers, while showing an impressive growth trajectory, are still quite low.

This belies the true size of the market and may lead observers to conclude that this technology is of limited relevance to manufacturing and is therefore not necessary to factor into a manufacturers’ IP strategy. But this assumption could prove to be a costly mistake.

Figure 2 captures patents that are aimed at innovation in techniques and technology around additive manufacturing. However, what the numbers fail to communicate is that the objects that can be 3D printed do not have to be patentable. Instead, they may be products that were previously manufactured using traditional manufacturing techniques (eg, milling, casting or metal stamping) and which may now be 3D printed with some minor. This approach to manufacturing makes increasing economic sense in a number of scenarios.

For instance, where the cost of raw materials is high, additive manufacturing provides large savings by avoiding the wastage caused by traditional subtractive manufacture. Instead of cutting away and disposing of a large amount of material, additive manufacturing uses the required amount of matter only as it builds up products through layering.

With regard to complex products, 3D printing can save on assembly costs while minimising manufacturing tolerances. Items can be printed in one – or at least fewer – parts. Even products with moving mechanisms can be printed in assembled form.

The Pirate Bay of manufacturing?

Herein lies the rub. The additive manufacturing technology field – as fascinating as it may be – is not where the bulk of IP issues are likely to reside. Instead, the problems are more likely to be a result of the fact that 3D printing lowers the barriers to market entry by reducing the need for technical skill in manufacturing. This increases the risk of counterfeiting, even for otherwise traditionally manufactured products.

To better illustrate this issue, rewind to the early 2000s, when online file sharing went mainstream and wreaked havoc in the music industry. There is a clear parallel to be made between the widespread copyright infringement caused through sharing online files and the potential for the distribution of digitised versions of manufactured products. Given that additive manufacturing allows products to be easily printed once the computer file has been obtained, it is easy to see how widespread circulation of these could cause similar issues for manufacturers.

Manufacturers have always utilised blueprints, which have existed in the form of computer-aided design (CAD) files for many years now. These can be easily converted into 3D-printable files. While conversion may still require some human intervention for optimum performance (although automated solutions are available), the automation provided by additive manufacturing greatly reduces the barrier to entry for manufacturing. At the extreme end of the scale, products that would otherwise require highly skilled machinists could instead be printed at home by a relatively unskilled individual.

This problem is further aggravated by the fact that, although cybersecurity, digital rights management and file tracking efforts may keep a file safe for a while, 3D scanners can reproduce digital models of a product in a very short time. There is therefore a risk of placing the security of the ‘digital twin’ of a manufactured product beyond the product innovators’ control.

We need only look at the music industry to understand the consequences of a printable file (or its easily convertible CAD precursor) falling into the wrong hands and being shared with potential infringers. Even if the file is used to create a protected product in a jurisdiction in which the relevant product protection exists, policing infringement and enforcing against even a moderate number of (small-scale) infringers is a logistical nightmare and can quickly cease to be economically tenable.

Future-proofing intellectual property

When mitigating these risks, traditional IP filing strategies may no longer be appropriate as these tend to focus on a select few countries, with an emphasis on key markets and important manufacturing hubs. As manufacturing moves away from these bases, IP strategies will need to adapt to effectively cover infringers.

A further issue is that many existing IP laws were drafted many years ago, before digital design files were in common use. The question of whether these laws are fit for purpose in a world of ever-increasing digitisation has been pondered by academics and legislators alike – although the European Commission has concluded that, while the new circumstances provide a challenge, the commonly used host of IP rights is still fit for purpose.

While this may come as a relief to many, it does not mean that IP rights, if used in a traditional way, will provide the desired protection. Indeed, the opposite seems to be the case. Discussions among academics with regard to whether a claim to a product also encompasses a product’s digital twin or the 3D-printer file required to manufacture it are ongoing.

Given the disagreements among academics, the prudent IP professional would do well not to rely on claims for the physical product but to extend protection to cover its digital twin. True, it is possible that case law in the next few years may provide clarity and claims for a product may be found to extend to a digital version , but at present this is mere speculation. Even if case law does develop in this regard, it would be unlikely to be uniform across the world and therefore unsuitable as a basis for a global IP strategy. Relying on claims for the physical product alone to prevent dissemination of printable files is likely to leave applicants hostages to fortune.

Moreover, given the differences around the world in the requirements for demonstrating indirect infringement by a file sharer, it is also inadvisable to rely on indirect infringement provisions to try to stop dissemination of digital twins around the world. Doing so is, at best, adventurous and realistically has no place in a well-developed IP strategy other than as a rather desperate stop-gap measure.

It is clear that, while attorneys that deal with new inventions designed for 3D printing may craft IP protection fit to protect the invention, the part of the patent profession handling tangible inventions that are not designed for additive manufacturing has yet to wake up to the threat of infringement that 3D printing poses. This is particularly the case where the inventor does not contemplate, or even suspect, the risk of infringement through additive manufacturing. Pair this with a patent attorney who is equally unaware of these concerns and the outcome is an IP strategy that is unlikely to protect an invention over the term of protection.

It is likely that IP portfolios have already suffered damage in this way. The effect that this has on the portfolio’s value depends very strongly on the way in which additive manufacturing is adopted in the industry concerned. Given that the degree of adoption is not predictable with any level of certainty, a wise practitioner would seek to mitigate this damage. Strategies for doing so exist and have, at least informally, been endorsed by one of the five major patent offices around the world. Inaction at this stage is evidently not an acceptable option, given that individual IP rights – especially patents – can generally be narrowed only and the scope of protection cannot be supplemented.

However, the good news is that if implemented correctly, the current host of IP rights can provide useful protection against the circulation of a product’s digital twin. Given the length of the term of protection of IP rights, it is imperative that this protection be obtained for all tangible goods, even in industries that are to date relatively unaffected by additive manufacturing.

The message is clear. Additive manufacturing is only just beginning and no industry is immune from the disruption that it will bring. Rights holders must future proof their intellectual property now – or risk suffering going the way of the CD.